Translating Vision into Action: FAS Commentary on the NSCEB Final Report and the Future of U.S. Biotechnology

Advancing the U.S. leadership in emerging biotechnology is a strategic imperative, one that will shape regional development within the U.S., economic competitiveness abroad, and our national security for decades to come. In the past few years, the contribution of biotechnology to the U.S. economy (referred to as the bioeconomy) has grown significantly, contributing over $210 billion to GDP and creating more than 640,000 domestic jobs, cementing its role as a major and expanding economic force. The impact of biotechnologies and biomanufacturing can be seen across diverse sectors and geographies, with applications spanning agriculture, energy, industrial manufacturing, and health. As biotechnology continues to drive innovation, it is emerging as a core engine of the next industrial revolution.

To maximize the strategic potential of emerging biotechnology, Congress established the bipartisan National Security Commission on Emerging Biotechnology (NSCEB) through the FY22 National Defense Authorization Act. The commission was tasked with conducting a comprehensive review of how advancements in biotechnology and related technologies will shape the current and future missions of the Department of Defense (DOD), and developing actionable policy recommendations to support the adoption and advancement of biotechnology within DOD and across the federal government. This effort culminated in a report, “Charting the Future of Biotechnology”, delivered to Congress in April 2025. The final report outlines 49 recommendations aimed at accelerating biotechnology innovation and scaling the U.S. biomanufacturing base, reinforcing the bioeconomy as a strategic pillar of national security and economic competitiveness.

In addition to developing a series of recommendations to promote and grow the U.S. bioeconomy, the Commission has also been tasked with facilitating the implementation and adoption of these policy recommendations by Congress and relevant federal agencies. To date, several pieces of legislation have been introduced in both the 118th and 119th Congress that incorporate recommendations from NSCEB’s interim and final reports (Table 1). This Legislation Tracker will be updated as this legislation moves through the process and as new bills are introduced.

The NSCEB report represents a critical policy opportunity for the U.S. bioeconomy. It proposes an injection of $15 billion to support sustained growth in biotechnology innovation and biomanufacturing through strategic investment and improved coordination. This level of investment is significant and would signal congressional support for the bioeconomy that goes beyond that seen in CHIPS and Science Act and the Inflation Reduction Act of 2022. This much needed infusion of federal investment offers a timely opportunity to build on existing momentum and unlock the next phase of U.S. leadership in the bioeconomy.

The recommendations in the report should be seen as opportunities for engagement with the Commission and with Congress for further refinement of these policy ideas. As the Commission begins its work on implementation, they have called on stakeholders across the bioeconomy to help refine and strengthen its proposals. Responding to this need, the Federation of American Scientists (FAS) has identified priority areas requiring greater clarity and has issued an open call for supplemental recommendations and policy proposals through the Day One Open Call process.

Overall, FAS supports the Commission’s final report and we applaud the Commission’s efforts to elevate the national conversation around emerging biotechnologies. The report provides a necessary foundation for long-term federal strategy and investment in biotechnology and biomanufacturing. At the same time, there remain clear opportunities to strengthen the recommendations through greater specificity and deeper stakeholder engagement. Two overarching decisions by the Commission deserve some additional scrutiny. First, the report’s adversarial framing towards China, while grounded in strategic reality, risks overlooking opportunities for targeted collaboration that could yield global benefits, particularly in areas where scientific progress depends on multinational cooperation. Second, the final report gives limited attention to the agricultural sector, despite its clear relevance to national security and the DOD’s growing interest in agricultural biotechnology. The “Additional Considerations” section does include a constructive call to modernize the USDA’s BioPreferred Program and update federal classification systems, recommendations that echo those issued by FAS. A more comprehensive approach toward this sector is needed.

The following sections summarize the report’s key pillars and provide analysis, highlighting core recommendations and identifying opportunities where additional detail and stakeholder input, through the Day One Open Call, will be essential for translating the report’s vision into actionable, high-impact policy. Additionally, the Supplementary Recommendations Table for the NSCEB Final Report (Table 2) lists each of the recommendations from the pillars and cross references related proposals from prior FAS work, subject matter experts, and Day One Memos submitted by external stakeholders.

Table 2: Supplementary Recommendations Table for the NSCEB Final Report

Pillar 1. Prioritize Biotechnology at the National Level

Pillar 1 of the report emphasizes the need to prioritize biotechnology at the national level. The recommendations within this pillar are essential for the development of a cohesive national strategy, and we encourage Congress to consider incorporating terminology and drawing on previous policy related to the bioeconomy to ensure that previous progress related to emerging biotechnologies is not lost.

A central recommendation within this Pillar is the establishment of the National Biotechnology Coordination Office (NBCO), which would reduce fragmentation and elevate biotechnology as a national priority. To succeed, the NBCO must address challenges faced by past coordination bodies and be empowered by the administration to drive cross-agency strategy despite differing institutional perspectives. While the presidential appointment of the director could lend authority, it also risks politicization and strategic shifts that may destabilize the sector. Success will depend on clarity of roles, coordination across functions, and strong institutional support for implementation.

FAS provided several additional recommendations and insights on these topics (see Table 2) to make them more nuanced and actionable by Congress, including:

- Coordinating the U.S. Government Approach to the Bioeconomy by Sarah Carter

- A National Bioeconomy Manufacturing and Innovation Initiative by Alexander Titus

Pillar 2. Mobilize the Private Sector to get U.S. Products to Scale

Pillar 2 of the final report focuses on mobilizing the private sector to strengthen biotechnology products by addressing key challenges to the sector, including regulatory reform, financing obstacles, and infrastructure and data needs. While the report correctly identifies long standing regulatory bottlenecks for products of biotechnology under the Coordinated Framework, including unclear oversight and interagency conflicts, it also acknowledges statutory complexities that make reform difficult. Empowering the Office of Management and Budget’s Office of Information and Regulatory Affairs (OIRA) to mediate these disputes is a promising approach, but would require statutory reinforcement. Similarly, proposals to modernize regulatory capacity, such as agency fellowships and regulatory science programs, highlight a critical need for technical expertise within government, though questions remain about institutional placement and long-term sustainability.

On financing and infrastructure, the report points to real gaps in early-stage capital and scale-up capacity, particularly for bridging the “Valley of Death” for biotechnology manufacturing. Concepts like advance market commitments and a new investment fund have potential, but their impact will depend heavily on design, risk management, and alignment with existing capital pipelines. The infrastructure recommendations are strong, but coordination challenges, particularly among national labs, regional hubs, and entities like BioMADE, must be addressed to avoid duplication or underutilization and approaches to securing bioeconomy infrastructure and data are underdeveloped. It will be critical to better define what constitutes critical biotechnology infrastructure and how it should be protected.

FAS provided significant expertise on these topics (see Table 2), such as:

- Coordinating the U.S. Government Approach to the Bioeconomy by Sarah Carter

- Regulations for the Bioeconomy by Sarah Carter

- A National Frontier Tech Public-Private Partnership to Spur Economic Growth by Katie Rae, Orin Hoffman & Michael Kearney

- De-Risking the U.S. Bioeconomy by Establishing Financial Mechanisms to Drive Growth and Innovation by Nazish Jeffery & Zak Weston

- Advancing the U.S. Bioindustrial Production Sector by Michael Fisher

- Closing Critical Gaps from Lab to Market by Phil Weilerstein, Shaheen Mamawala, and Heath Naquin

- Strengthening the U.S. Biomanufacturing Sector Through Standardization by Chris Stowers

- Summary Report – December 7, 2022, Bioeconomy Policy Workshop: Financial and Economic Tools

- Project BOoST: A Biomanufacturing Test Facility Network for Bioprocess Optimization, Scaling, and Training by Ed Charles & Chris Fracchia

One of the NSCEB’s recommendations in particular would benefit from additional input from external subject matter experts to make it more concrete and actionable for Congress:

- Recommendation 2.2d: Congress should improve the effectiveness and reach of the Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) programs to support early-stage innovation. Specifically, stakeholder input on:

- Which areas of biotechnology or sectors within the bioeconomy would most benefit from SBIR and STTR investment?

- How can these programs better support not only early- but also late-stage innovation?

If you have specific policy suggestions related to this topic, we encourage you to submit your ideas through the Day One Open Call page at FAS.

Pillar 3. Maximize the Benefits of Biotechnology for Defense

Pillar 3 of the final report focuses on maximizing the benefits of biotechnology for national defense, with an emphasis on the intelligence community and the Department of Defense (DOD). This pillar includes recommendations related to BioMADE oversight as well as internal workforce education on biotechnology. While oversight of BioMADE is important, it is unclear why additional oversight from Congress is needed for this manufacturing institute above and beyond that provided by its federal sponsor. Additionally, it will be essential for DOD to establish a mechanism for regularly updating workforce education in biotechnology, given the sector’s rapid and continuous evolution.

More broadly, this Pillar appropriately reframes biotechnology as a strategic capability, beyond its traditional role in R&D. This shift in perspective is timely, but realizing the potential of these technologies will require significant institutional change. Ethical use frameworks, particularly around dual-use risks (warfighter enhancement, surveillance, and environmental impact) must be developed through a transparent process that extends beyond DOD to include external stakeholders and independent organizations. In addition, proposed investment and export controls aimed at limiting adversarial advantage must be carefully scoped and implemented. The Department of Commerce (DOC) has published multiple Requests for Information (2018, 2020) to understand and delineate “high-risk” biotech products. Yet, DOC has not added new biotech products to the export list, which highlights the complexity of this task, and underscores the need for precision to avoid stifling beneficial collaboration or disrupting global supply chains.

FAS provided several additional recommendations and insights on these topics (see Table 2) to make them more nuanced and actionable by Congress, including:

- CLimate Improvements through Modern Biotechnology (CLIMB) — A National Center for Bioengineering Solutions to Climate Change and Environmental Challenges by Jennifer Panlilio & Hanny Rivera

- A Foundational Technology Development and Deployment Office to Create Jobs by Katie Rae, Michael Kearney, and Orin Hoffman

Pillar 4. Out-Innovate our Strategic Competitors

Pillar 4 of the NSCEB’s report offers recommendations for strengthening the biotechnology sector to out-innovate global competitors. It focuses on building robust data ecosystems, enhancing biosecurity, and expanding bio R&D infrastructure within the U.S. A central theme is the creation of a modern biological data ecosystem, which would provide the foundational infrastructure necessary to accelerate innovation. While a biological data ecosystem and associated standards are timely, several technical and governance challenges must be addressed, like harmonizing legacy systems, defining AI-readiness, and coordinating cloud lab integration. These complexities present an opportunity for stakeholder engagement and thoughtful design.

Within the Pillar, proposals that call for expanding National Lab capabilities and funding interdisciplinary biotechnology research are directionally strong, but success will depend on interagency coordination and alignment with industry needs. Finally, the report calls for stronger governance of biosafety and biosecurity, though its assertion that past efforts have “failed” could benefit from more nuanced analysis.

While FAS provided expertise on these topics (see Table 2), such as:

- A National Bioeconomy Manufacturing and Innovation Initiative by Alexander Titus

- Kickstarting Collaborative, AI-Ready Datasets in the Life Sciences with Government-funded Projects by Erika DeBenedictis, Ben Andrew, and Pete Kelly

- Creating a National Exposome Project by Gurdane Bhutani, Gary Miller, and Sandeep Patel

- Accelerating Biomanufacturing and Producing Cost-Effective Amino Acids through a Grand Challenge by Allison Berke

- Accelerating Bioindustry Through Research, Innovation, and Translation by Jon Roberts

A few of the report’s recommendations would benefit from additional stakeholder input to enhance clarity and ensure they are actionable for Congress:

- Recommendation 4.1c: Congress should authorize and fund the Department of Interior to create a Sequencing Public Lands Initiative to collect new data from U.S. public lands that researchers can use to drive innovation and Recommendation 4.1d: Congress should authorize the National Science Foundation to establish a network of “cloud labs,” giving researchers state-of-the-art tools to make data generation easier. Specifically, stakeholder input on:

- What type of data should be generated and what types of data generation or collection should be prioritized?

- How can we best draw on or expand existing cloud lab capabilities?

- Recommendation 4.3b: Congress should initiate a grand research challenge focused on making biotechnology predictably engineerable. Specifically, stakeholder input on:

- What specific grand challenge should Congress pursue and how should it be implemented?

- How should the U.S. government engage the scientific community (and others) in establishing and pursuing grand challenges for biotechnology?

- Recommendation 4.4a: Congress must direct the executive branch to advance safe, secure, and responsible biotechnology research and innovation. Specifically, stakeholder input on:

- The report calls for establishment of a body within the U.S. government for this purpose. What should this look like and how would it operate?

If you have specific policy suggestions related to these topics, we encourage you to submit your ideas through the Day One Open Call at FAS.

Pillar 5. Build the Biotechnology Workforce of the Future

Pillar 5 of the final report looks to the future by offering recommendations to secure and build the biotechnology workforce needed in the future. It addresses both the modernization of the federal biotech workforce and the development of the broader U.S. biotech workforce. Modernizing the federal workforce requires more than training programs. It requires coordination across HR systems, consistent standards, and better integration of biotechnology experts into national security and diplomacy. Proposals to expand Congressional science capacity are long overdue and necessary to equip lawmakers to address rapidly evolving biotechnology issues. On the national level, scaling the biomanufacturing workforce will depend on aligning credentials with industry needs and securing input from labor, academia, and employers. Expanding biotechnology education is promising, but successful implementation will require investment in teacher training and curriculum development.

While FAS contributed several recommendations to support this critical capacity-building effort (see Table 2), such as:

- Gathering Industry Perspectives on how the U.S. Government can Support the Bioeconomy by Sarah Carter

- Meeting Biology’s “Sputnik Moment”: A Plan to Position the United States as a World Leader in the Bioeconomy by Natalie Kuldell

One of the NSCEB’s recommendation would benefit from additional stakeholder input to enhance its clarity and make it more actionable for Congress:

- Recommendation 5.2a: Congress must maximize the impact of domestic biomanufacturing workforce training programs. Specifically, stakeholder input on:

- How should the government approach creating competency models for biomanufacturing training and microcredentialing?

- Which specific areas are best suited for microcredentialing efforts?

If you have specific policy suggestions related to these topics, we encourage you to submit your ideas through the Day One Open Call at FAS.

Pillar 6. Mobilize the Collective Strengths of our Allies and Partners

Pillar 6 of the final report focuses on strengthening alliances and partnerships on the global stage to enhance the U.S. biotechnology sector. It highlights the role of the State Department (DOS) in facilitating this effort through development of foreign policy tools, strengthening global data and market infrastructure, and leading in the establishment of international standards within the sector. Elevating biotechnology within U.S. foreign policy is both timely and necessary, particularly as biotech becomes increasingly strategic in areas like health security, climate resilience, and defense. Leveraging existing tools like the International Technology Security and Innovation (ITSI) Fund could provide a solid foundation, but effective execution will require clearer interagency coordination, transparency in funding allocation, and defined metrics for impact, especially across overlapping technology domains.

Proposals to create shared data infrastructure, joint purchasing mechanisms, and international fellowships point to smart long-term strategies for building trust and interoperability with allies. Yet, success hinges on careful coordination, especially around sensitive areas like dual-use biotechnology export controls. If U.S. standards are significantly more restrictive than those of allies, it could create friction and undermine broader goals of international collaboration and leadership.

FAS provided several additional recommendations and insights on these topics (see Table 2) to make them more nuanced and actionable by Congress, including:

- A Matter of Trust: Helping the Bioeconomy Reach Its Full Potential with Translational Governance by Christopher J. Gillespie

- Strategic Investments the U.S. Should Make in the Bioeconomy Right Now by Nazish Jeffery

- Strengthening U.S. Engagement in International Standards Bodies by Natalie Thompson and Mark Montgomery

- What’s Next for the U.S. Bioeconomy? Defining It. by Nazish Jeffery

One particularly important recommendation emphasizes the need to engage the public and build trust in the sector by collecting data on public acceptance. This data can help inform national governance and ensure it is more responsive and translatable to public concerns.

Additional Considerations

The additional considerations section of the NSCEB report brings several key recommendations that do not fit with the rest of the report, though are still very important. Many focus on aligning federal leadership and economic infrastructure with the needs of a growing and strategically vital biotechnology sector. Elevating biotechnology leadership within DOD is a logical step to align R&D with budget authority and operational needs. Similarly, expanding the scope of the Bioenergy Technologies Office (BETO) beyond biofuels and codifying the Office of Critical and Emerging Technology (OCET) role reflects an overdue shift toward recognizing biotech’s relevance to national security and broader innovation policy, though these changes will require institutional buy-in and cultural adjustment. On the economic side, proposals to create a public-private innovation consortium are timely, especially for supporting smaller firms and navigating the convergence of biotechnology with other technologies, like AI. However, care should be taken to not overly narrow the scope at the expense of other critical intersections.

While FAS provided a few recommendations on these topics (see Table 2), such as:

- Summary Report – December 5, 2022, Bioeconomy Policy Workshop: Measurement and Language

- Laying the Groundwork for the Bioeconomy by Sarah Carter

One of the report’s recommendations would benefit from additional stakeholder input to enhance clarity and ensure that it is actionable for Congress:

- Recommendation 8: Congress should direct the National Science Foundation (NSF) to establish a federal grant program for a national system of community biology labs that would engage Americans in informal learning. Specifically, stakeholder input on:

- What is most needed to support community biology labs?

- Should community labs be incorporated within universities or run as independent institutions?

If you have specific policy suggestions related to these topics, we encourage you to submit your ideas through the Day One Open Call at FAS.

Next Steps for the U.S. Bioeconomy

The NSCEB’s final report outlines a vision for a national biotechnology strategy aimed at securing U.S. leadership in a sector that is not only rapidly advancing but also delivering significant economic returns, outpacing even AI. While the report offers thoughtful, well-grounded recommendations that address many of the core challenges facing the U.S. biotechnology landscape, several proposals would benefit from greater specificity and refinement to make them actionable in legislative form. This moment presents a unique opportunity for stakeholders across the biotechnology ecosystem to contribute meaningfully to the development of a national bioeconomy strategy.

The U.S. bioeconomy, which encompasses biotechnology, holds enormous strategic and economic potential. Without a clear, well-implemented plan, the nation risks repeating the mistakes of past industrial shifts, such as the decline in domestic semiconductor leadership. FAS urges Congress to act on the Commission’s recommendations and leverage FAS’ additional proposals to strengthen them further (see Table 2). We also call on the scientific community to provide additional input on these recommendations to ensure they are viable and impactful. If you have actionable policy ideas on how to shape the path forward for the U.S. bioeconomy, we encourage you to submit them through the Day One Open Call. Applicants with compelling ideas will be partnered with our team at FAS to develop their idea into an implementation ready policy memo. Click here to learn more about the Day One Open Call.

FAS Bioeconomy Open Call Areas

- Recommendation 2.2d (SBIR and STTR): Congress should improve the effectiveness and reach of the Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) programs to support early-stage innovation.

- Which areas of biotechnology or sectors within the bioeconomy would most benefit from SBIR and STTR investment?

- How can these programs better support not only early- but also late-stage innovation?

- Recommendation 4.1c (Bio Data Generation): Congress should authorize and fund the Department of Interior to create a Sequencing Public Lands Initiative to collect new data from U.S. public lands that researchers can use to drive innovation and Recommendation 4.1d: Congress should authorize the National Science Foundation to establish a network of “cloud labs,” giving researchers state-of-the-art tools to make data generation easier.

- What type of data should be generated and what types of data generation or collection should be prioritized?

- How can we best draw on or expand existing cloud lab capabilities?

- Recommendation 4.3b (Predictable BioEngineering): Congress should initiate a grand research challenge focused on making biotechnology predictably engineerable.

- What specific grand challenge should Congress pursue and how should it be implemented?

- How should the U.S. government engage the scientific community (and others) in establishing and pursuing grand challenges for biotechnology?

- Recommendation 4.4a (Safe, Secure, Responsible): Congress must direct the executive branch to advance safe, secure, and responsible biotechnology research and innovation.

- The report calls for establishment of a body within the U.S. government for this purpose. What should this look like and how would it operate?

- Recommendation 5.2a (Domestic Bio Workforce): Congress must maximize the impact of domestic biomanufacturing workforce training programs.

- How should the government approach creating competency models for biomanufacturing training and microcredentialing?

- Which specific areas are best suited for microcredentialing efforts?

- Additional Considerations #8 (Grant Programs): Congress should direct the National Science Foundation (NSF) to establish a federal grant program for a national system of community biology labs that would engage Americans in informal learning.

- What is most needed to support community biology labs?

- Should community labs be incorporated within universities or run as independent institutions?

De-Risking the U.S. Bioeconomy by Establishing Financial Mechanisms to Drive Growth and Innovation

The bioeconomy is a pivotal economic sector driving national growth, technological innovation, and global competitiveness. However, the biotechnology innovation and biomanufacturing sector faces significant challenges, particularly in scaling technologies and overcoming long development timelines that don’t align with short-term return expectations from investors. These extended timelines and the inherent risks involved lead to funding gaps that hinder the successful commercialization of technologies and bio-based products. If obstacles like the ‘Valleys of Death, a lack of capital at crucial development junctures, that companies and technology struggle to overcome are not addressed, this could result in economic stagnation and the U.S. losing its competitive edge in the global bioeconomy.

Government programs like SBIR and STTR lessen the financial gap inherent in the U.S. bioeconomy, but existing financial mechanisms have proven insufficient to fully de-risk the sector and attract the necessary private investment. In FY24, the National Defense Authorization Act established the Office of Strategic Capital within the Department of Defense to provide financial and technical support for its 31 ‘Covered Technology Categories’, which includes biotechnology and biomanufacturing. To address the challenges associated with de-risking biotechnology and biomanufacturing within the U.S. bioeconomy, the Office of Strategic Capital within the Department of Defense should house a Bioeconomy Finance Program. This program would offer tailored financial incentives such as loans, tax credits, and volume guarantees, targeting both short-term and long-term scale-up needs in biomanufacturing and biotechnology.

By providing these essential funding mechanisms, the Bioeconomy Finance Program will reduce the risks inherent in biotechnology innovation, encouraging more private sector investment. In parallel, states and regions across the country should develop regional specific strategies, like investing in necessary infrastructure, and fostering public-private partnerships, to complement the federal government’s initiatives to de-risk the sector. Together, these coordinated efforts will create a sustainable, competitive bioeconomy that supports economic growth, and strengthens U.S. national security.

Challenge & Opportunity

The U.S. bioeconomy encompasses economic activity derived from the life sciences, particularly in biotechnology and biomanufacturing. The sector plays an important role in driving national growth and innovation. Given its broad reach across industries, impact on job creation, potential for technological advancements, and requirement for global competitiveness, the U.S. bioeconomy is a critical sector for U.S. policymakers to support. With continued development and growth, the U.S. bioeconomy promises not only economic benefits, but also strengthens national security, health outcomes, and environmental sustainability for the country.

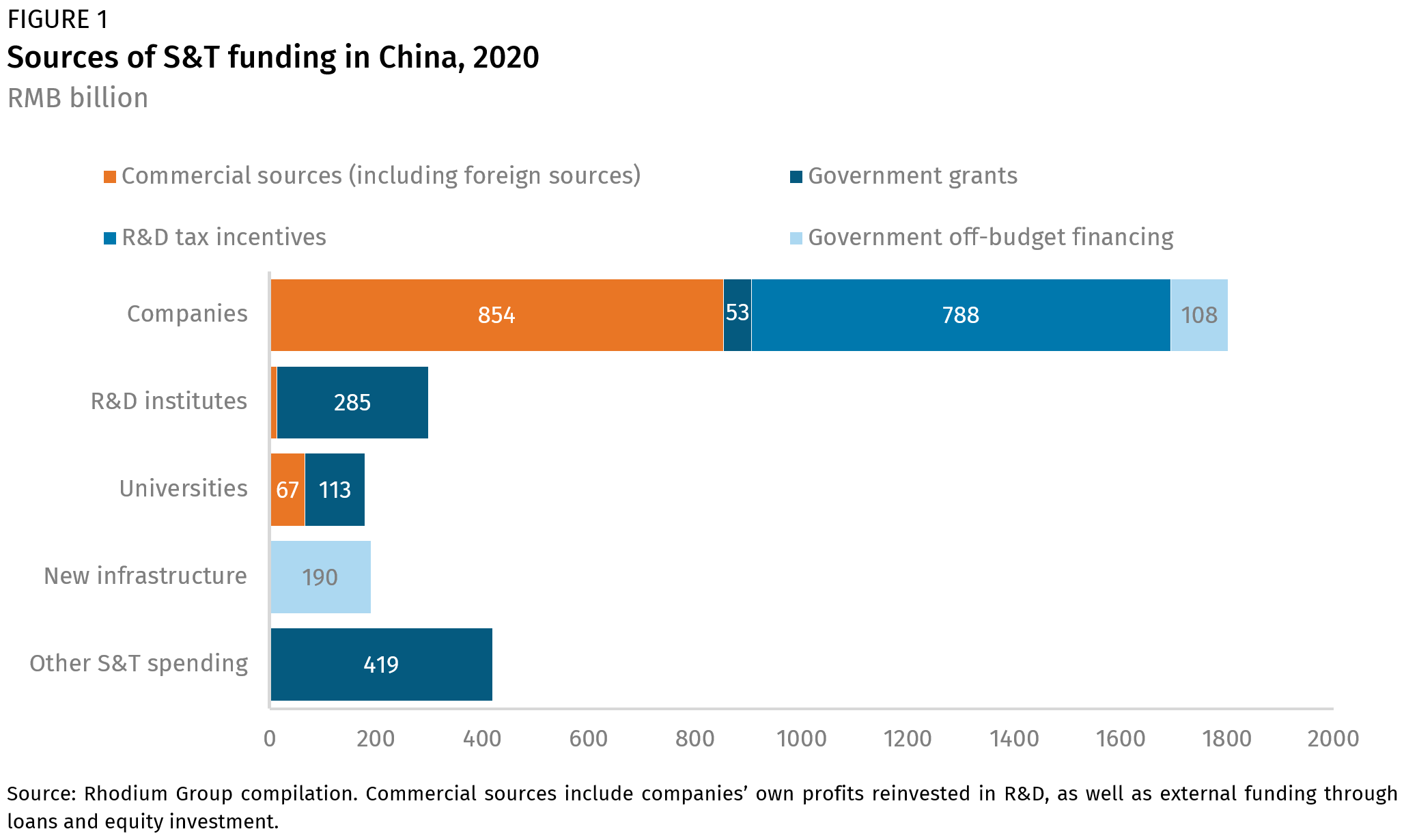

Ongoing advancements in biotechnology, including artificial intelligence and automation, have accelerated the growth of the bioeconomy, making the sector both globally competitive and an important domestic economic sector. In 2023, the U.S. bioeconomy supported nearly 644,000 domestic jobs, contributed $210 billion to the GDP, and generated $49 billion in wages. Biomanufactured products within the bioeconomy span multiple categories (Figure 1). Growth here will drive future economic development and address societal challenges, making the bioeconomy a key priority for government investment and strategic focus.

Biomanufactured products span a wide range of categories, from pharmaceuticals and chemicals, which require small volumes of biomass but yield high-value products, to energy and heat, which require larger volumes of biomass but result in lower-value products. Additionally, there are common infrastructure synergies, bioprocesses, and complementary input-output relationships that facilitate a circular bioeconomy within bioproduct manufacturing. Source: https://edepot.wur.nl/407896

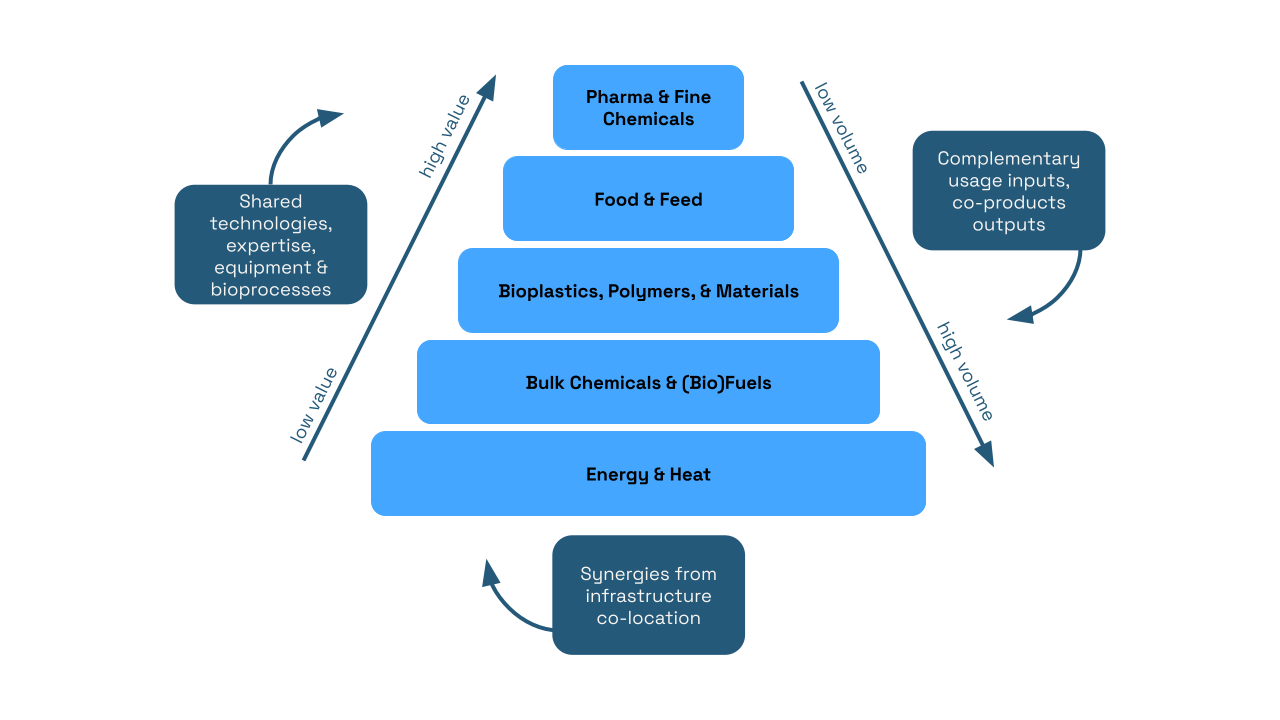

An important driving force for the U.S. bioeconomy is biotechnology and biomanufacturing innovation. However, bringing biotechnologies to market requires substantial investment, capital, and most importantly, time. Unlike other technology sectors which see returns on investment within a short period of time, often, there is a misalignment between scientific and capitalistic expectations. Many biotechnology based companies rely on venture capital, a form of private equity investments, to finance their operations. However, venture capitalists (VCs) typically operate on short return on investment timelines, which may not align with the longer development cycles characteristic of the biotechnology sector (Figure 2). Additionally, the need for large-scale and the high capital expenditures (CAPEX) required for commercially profitable production, along with the low-profit margins in high-volume commodity production, create further barriers to obtaining investment. While this misalignment is not universal, it remains a challenge for many biotech startups.

The U.S. government has implemented several programs to address the financing void that often arises during the biotechnology innovation process. These include the Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) programs, which provide phased funding across all Technology Readiness Levels (TRLs); the DOE Loan Program Office, which offers debt financing for energy-related innovations; the DOE Office of Clean Energy Demonstrations which provides funding for demonstration-scale projects that provide proof of concept; and the newly established Office of Strategic Capital (OSC) within the DOD (as outlined in the FY24 National Defense Authorization Act), which is tasked with issuing loans and loan guarantees to stimulate private investment in critical technologies. An example is the office’s new Equipment Loan Financing through OSC’s Credit Program.

Biotechnology development timelines typically take around ~10+ years to complete and reach the market due to longer R&D and Demonstration & Scale-Up phases, while non-biotechnology development timelines are generally much shorter, averaging around ~5+ years.

While these efforts are important, they are insufficient on their own to de-risk the sector to the degree which is needed to realize the full potential of the U.S. bioeconomy. To effectively support the biotechnology innovation pipeline at critical stages, the government must explore and implement additional financial mechanisms that attract more private investment and mitigate the inherent risks associated with biotechnology innovation. Building on existing resources like the Regional Technology and Innovation Hubs, NSF Regional Innovation Engines, and Manufacturing USA Institutes, help stimulate private sector investment and are crucial for strengthening the nation’s economic competitiveness.

The newly established Office of Strategic Capital (OSC) within the DOD is well-positioned to enhance resilience in critical sectors for national security, including biotechnology and biomanufacturing, through large-scale investments. Biotechnology and biomanufacturing inherently require significant CAPEX, expenses related to the purchase, upgrade, or maintenance of physical assets. This requires substantial amounts of strategic and concessional capital to de-risk and accelerate the biomanufacturing process. By creating, implementing, and leveraging various financial incentives and resources, the Office of Strategic Capital can help build the robust infrastructure necessary for private sector engagement.

To achieve this, the U.S. government should create the Bioeconomy Finance Program (BFP) within the OSC, specifically tasked with enabling and de-risking the biotechnology and biomanufacturing sectors through financial incentives and programs. The BFP should focus on different levels of funding based on the time required to scale, addressing potential ‘Valleys of Death’ that occur during the biomanufacturing and biotechnology innovation process. These funding levels would target short-term (1-2 years) scale-up hurdles to accelerate the biotechnology and biomanufacturing process, as well as long-term (3-5 years) scale-up challenges, providing transformative funding mechanisms that could either make or break entire sectors.

In addition to the federal programs within the BFP to de-risk the sector, states and regions must also make substantial investments and collaborate with federal efforts to accelerate biomanufacturing and biotechnology ecosystems within their own areas. While the federal government can provide a top-down strategy, regional efforts are critical for supporting the sector with bottom-up strategies that complement and align with federal investments and programs, ultimately enabling a sustainable and competitive biotechnology and biomanufacturing industry regionally. To facilitate this, regions should develop and implement state-wide investment initiatives like resource analysis, infrastructure programs, and a cohesive, long-term strategy focused on public-private partnerships. The federal government can encourage these regional efforts by ensuring continued funding for biotechnology hubs and creating additional opportunities for federal investment in the future.

Plan of Action

To strengthen and increase the competitiveness of the U.S. bioeconomy, a coordinated approach is needed that combines federal leadership with state-level action. This includes establishing a dedicated Bioeconomy Finance Program within the Office of Strategic Capital to create targeted financial mechanisms, such as loan programs, tax incentives, and volume guarantees. Additionally, states must be empowered to support commercial-scale biomanufacturing and infrastructure development, leveraging tech hubs, cross-regional partnerships, and building public-private partnerships to build capacity and foster innovation nationwide.

Recommendation 1. Establish and Fund a Bioeconomy Finance Program

Congress, in the next National Defense Authorization Act, should codify the Office of Strategic Capital (OSC) within DOD and authorize the creation of a Bioeconomy Finance Program (BFP) within the OSC to provide centralized federal structure for addressing financial gaps in the bioeconomy, thereby increasing productivity and competitiveness globally. In 2024, Congress expanded the OSCs mission to offer financial and technical support to entities within its 31 ‘Covered Technology Categories,’ including biotechnology and biomanufacturing. Additionally, in order to build resilience in the sector and maintain a competitive advantage globally while also strengthening national security, these substantial expenditures should be housed within the OSC. Establishing the BFP within the OSC at the DOD would allow for a targeted focus on these critical sectors, ensuring long-term stability and resilience against political shifts.

The DOD and OSC should leverage its own funding as well as its existing partnership with the Small Business Administration to direct $1 billion to set up the BFP to create and implement initiatives aimed at de-risking the U.S. bioeconomy. The Bioeconomy Finance Program should work closely with relevant federal agencies, such as the DOE, Department of Agriculture (USDA), and the Department of Commerce (DOC), to ensure a long-term cohesive strategy for financing bioeconomy innovation and biomanufacturing capacity.

Recommendation 2. Task the Bioeconomy Finance Program with Key Initiatives

A key element of the OSC’s mission and investment strategy is to provide financial incentives and support to entities within its 31 ‘Core Technology Categories’. By having BFP design and manage these financial initiatives for the biotechnology and biomanufacturing sectors, the OSC can leverage lessons from similar programs, such as the DOE’s loan program, to address the unique needs of these critical industries, which are essential for national security and economic growth.

Currently, the OSC has launched a credit program for equipment financing. While this is a necessary first step in fulfilling the office’s mission, the program is open to all 31 ‘Core Technology Categories’, resulting in broad, dilutive funding. To accelerate the bioeconomy and reduce risks in biotechnology and biomanufacturing, it is crucial to allocate resources specifically to these sectors. Therefore, BFP should take the lead in several key financial initiatives to support the growth of the bioeconomy, including:

Loan Programs

The BFP should develop specific biotechnology enabling loan programs, in addition to the new equipment loan financing program run by the OSC. These loan programs should be modeled after those in the DOE LPO, focusing on biomanufacturing scale-up, technology transfer, and overcoming financing gaps that hinder commercialization.

Example loan programs:

- DOE Title 17 Clean Energy Financing Program

- USDA Business & Industry Loan Guarantee

- Solar Foods EU Grant/Loan

Tax Incentives

The BFP office should create tax incentives tailored to the bioeconomy, such as, transferable investment and production tax credits. For example, the 45V tax credit for production of clean hydrogen could serve as a model for similar incentives aimed at other bioproducts.

Example tax incentives:

- The Inflation Reduction Act’s transferable tax credits are the gold standard for this category.

Volume Guarantees & Procurement Support

To mitigate risks in biomanufacturing, the office should establish volume guarantees for various bioproducts, offering financial assurance to manufacturers and encouraging private sector investment. An initial assessment should be conducted to identify which bioproducts are best suited for such guarantees. Additionally, the office should explore the possibility of procurement programs to increase government demand for bio-based products, further incentivizing industry growth and innovation. This effort should be undertaken in coordination with the USDA’s BioPreferred Program to minimize redundancy and to create a cohesive procurement strategy. In addition, the BFP should look to the procurement innovations promoted by the Office of Federal Procurement Policy to find solutions for forward funding to create a functioning market.

Example Volume Guarantees & Procurement Support:

- Heavy Forging Press Infrastructure Lease Agreement

- NASA and USAF buying Fairchild semiconductors in advance of needing them, and overbought performance

- Advance Market Commitments

- Joint Venture Partnerships

- Other Transaction Authorities

Recommendation 3. Develop Pipeline Programs to Address Financial and Time Horizon Needs

Utilizing the key initiatives highlighted above, the BFP should create a two-tiered financial mechanisms pipeline and program to address both the short-term and long-term financial needs. The different financial levels could potentially include:

- Level 1 – Short Term Scale-Up (1-2 years) Programs

- Subsidized cost of electricity and other utilities (waste, wastewater treatment, natural gas, energy, etc.)

- Funding for demonstration-scale projects and early-stage engineering development. Similar to the DOEs Office of Clean Energy Demonstrations or the DODs’ Defense Industrial Base Consortium round one $1-2M engineering grants)

- Tax holidays for corporate taxes and property taxes

- Allowing accelerated depreciation to reduce tax liabilities

- Land grants or subsidies for manufacturing assets

- Fast-track permitting and site preparation to avoid long waits

- Labor and workforce subsidies

- Removal of export duties on products created in the U.S. and shipped overseas

- Level 2 – Long Term Scale-Up (3-5 years) Programs

- Large-scale transferable tax credits (either production or investment tax credits) for manufacturing. Similar to the tax credits seen in the Inflation Reduction Act for clean energy.

- Large-scale manufacturing grants

- Large-scale, low-interest manufacturing loans and loan guarantees

- Government procurement contracts or commitment for offtake, such as partial/full volume guarantees

- Government direct or indirect equity investments in biomanufacturing and biotechnology innovations

Recommendation 4. State-Level Initiatives, Infrastructure Development, and Public-Private Partnerships

While federal efforts are crucial, a bottom-up approach is needed to support biomanufacturing and the bioeconomy at the state level. The federal government can support these regional activities by providing targeted funding, policy guidance, and financial incentives that align with regional priorities, ensuring a coordinated effort toward industry growth. States should be encouraged to complement federal initiatives by developing programs that support commercial-scale biomanufacturing. Key actions include:

- State-Level Bioeconomy Resource Analysis: Each state and region should conduct their own analysis to understand the bioeconomy resources at their disposal and determine what relevant resources they would need to establish or strengthen state or regional bioeconomies. Identifying these resources will help the nation understand its true bioeconomic potential by understanding where certain biomass is contained, what facilities are available and needed to develop an economically sustainable bioeconomy, and create data to better understand the economic return on investment.

- Once the analysis is completed, States should collaborate with federal agencies like the DOE, DOC, and Economic Development Administration (EDA) to create and apply for specialized grants for commercial-scale biomanufacturing facilities based off of these analyses. Grants should prioritize non-pharmaceutical biomanufacturing to expand the scope of bioeconomy growth beyond traditional sectors.

- Utility Infrastructure Grants: Another critical area is the creation of utility infrastructure needed to support biomanufacturing, such as wastewater treatment and electricity infrastructure. States should receive targeted funding for these infrastructure projects, which are essential for scaling up production. States should take these targeted funds and establish their own granting mechanism to build necessary, regional infrastructure that is needed long-term to support the U.S. bioeconomy.

- Tech Hub Partnerships: States should leverage existing tech hubs to serve as centers for innovation in bioeconomy technologies. These hubs, which are already positioned in regions with high technological readiness, can be incentivized to partner with other regions that may not yet have robust tech ecosystems. The goal is to create a collaborative, cross-regional network that fosters knowledge-sharing and builds capacity across the country.

- Foster Public-Private Partnerships (PPP): To ensure the success and sustainability of these initiatives, states should actively foster PPPs that bring together government, industry leaders, and academic institutions. These partnerships can help align private sector investment with public goals, enhance resource sharing, and accelerate the commercialization of bioeconomy technologies. By engaging in collaborative R&D, sharing infrastructure costs, and co-developing new biotechnologies, PPPs will play a crucial role in driving innovation and economic growth in the bioeconomy sector. In addition to fostering PPPs, regions should proactively work on creating models that enable these partnerships to become self-sustaining, helping to mitigate potential financial pitfalls if partners drop out of the partnership. By not only creating PPPs, but also ensuring they become fully independent over time, the associated risks with PPPs decrease significantly.

By addressing these steps at both the federal and state levels, the U.S. can create a robust, scalable framework for financing biomanufacturing and the broader bioeconomy, supporting the transition from early-stage innovation to commercial success and ensuring long-term economic competitiveness. A good example of how this approach works is the DOE Loan Program Office, which collaborates with state energy financing institutions. This partnership has successfully supported various projects by leveraging both federal and state resources to accelerate innovation and drive economic growth. This model makes sense for biomanufacturing and biotechnology within the BFP in the OSC, as it ensures coordination between federal and state efforts, de-risks the sector, and facilitates the scaling of transformative technologies.

Conclusion

Biotechnology innovation and biomanufacturing are critical components of the U.S. bioeconomy which drives innovation, economic growth, and global competitiveness, but these sectors face significant challenges due to the misalignment of development timelines and investment cycles. The sector’s inherent risks and long development processes create funding gaps, hindering the commercialization of vital biotechnologies and products. These challenges, including the ‘Valleys of Death,’ could stifle innovation, slow down progress, and result in the U.S. losing its global leadership in biotechnology if left unaddressed.

To overcome these obstacles, a coordinated and comprehensive approach to de-risk the sector is necessary. The establishment of the Bioeconomy Finance Program (BFP) within the DOD’s Office of Strategic Capital (OSC) offers a robust solution by providing targeted financial incentives, such as loans, tax credits, and volume guarantees, designed to de-risk the sector and attract private investment. These financial mechanisms would address both short-term and long-term scale-up needs, helping to bridge funding gaps and accelerate the transition from innovation to commercialization. Furthermore, building on existing government resources, alongside fostering state-level initiatives such as infrastructure development, and public-private partnerships, will create a holistic ecosystem that supports biotechnology and biomanufacturing at every stage and will substantially de-risk the sector. By empowering regions to develop their own bioeconomy strategies and leverage local federal government programs, like the EDA Tech Hubs, the U.S. can create a sustainable, scalable framework for growth. By taking these steps, the U.S. can strengthen both its economic position but also lead the world in development of transformative biotechnologies.

BioMADE, a Manufacturing Innovation Institute sponsored by the U.S. Department of Defense, plays an important role in advancing and developing the U.S. bioeconomy. Yet, BioMADE currently funds pilot to intermediate-scale projects, rather than commercial-scale projects. This leaves a significant funding gap, creating a distinct and significant challenge for the bioeconomy.. By contrast, the BFP within OSC would complement existing efforts by specifically targeting and mitigating risks in the biotechnology and biomanufacturing pipeline that current programs do not address. Furthermore, given that BioMADE is also funded by the DOD, enhanced coordination between these programs willenable a more robust and cohesive strategy to accelerate the growth of the U.S. bioeconomy.

While Private-Public Partnerships (PPPs) are already embedded in some federal regional programs, such as the EDA Tech Hubs, not all states or regions have access to these initiatives or funding. To ensure equitable growth and fully harness the economic potential of the bioeconomy across the nation, it will be important for regions and states to actively seek additional partnerships beyond federally-driven programs. This will empower them to build their own regional bioeconomies, or microbioeconomies, by tapping into regional strengths, resources, and expertise to drive localized innovation. Moreover, federal programs like EDA Tech Hubs are often focused on advancing existing technologies, rather than fostering the development of new ones. By expanding PPPs across the biotech sector, states and regions can spur broader economic growth and innovation by holistically developing all areas of biotechnology and biomanufacturing, enhancing the overall bioeconomy.

Strategic Investments the U.S. Should Make in the Bioeconomy Right Now

In 2023, the U.S. bioeconomy generated 643,992 domestic jobs and contributed $210.4 billion to the U.S. GDP, establishing it as a significant economic force. This impact is largely due to its broad and diverse scope. While the U.S. bioeconomy does not have a consensus definition, nearly all versions of the definition include biotechnology as a central driver. Consequently, a wide range of industries are encompassed within the bioeconomy (Table 1). Previous administrations, including the previous Trump Administration, have championed and advanced biotechnology and biomanufacturing. The Biden Administration released the Executive Order on Advancing Biotechnology and Biomanufacturing Innovation for a Sustainable, Safe, and Secure American Bioeconomy (Bioeconomy EO) focused on expanding domestic biomanufacturing capacity, streamlining regulations for biotech products, and expanding market opportunities. With a new chapter ahead of us, the United States is presented with incredible challenges and opportunities in the face of China’s dominance in this space.

However, the broad scope of the U.S. bioeconomy also presents significant challenges. While there is general consensus on the types of industries relevant to the bioeconomy, there is no definitive agreement on which should be included or excluded, resulting in certain sectors within an industry being classified as part of the bioeconomy even if the industry as a whole is not. This lack of clarity creates confusion which could result in missed opportunities for ongoing development and support programs that these industries could benefit from. Furthermore, this ambiguity fosters the creation of artificial silos, hindering cross-sector communication and potentially causing a loss of valuable collaborative capabilities. This lack of clarity additionally complicates the measurement of the bioeconomy’s economic contributions, leaving valuable opportunities for growth and development underexplored due to an inability to identify sectors that require further investment.

The Bioeconomy EO made significant strides in understanding the U.S. bioeconomy, but substantial growth remains. A key lesson learned is the need for a common, consensus-based definition and lexicon to improve communication across sectors, as agencies like the DOD, USDA, and DOE often struggle to talk across sectors without a shared language. NIST’s Bioeconomy Lexicon, last updated in February 2025, remains incomplete, with important terms like continuous fermentation still undefined. Additionally, there is a growing need for standards and metrics, and continued investment in NIST’s initiatives, which are essential to build a unified strategy that maximizes the bioeconomy’s full potential.

Despite these difficulties, the U.S. bioeconomy continues to demonstrate resilience and growth, particularly as we enter the next technological revolution driven by advancements in artificial intelligence, biotechnology, advanced manufacturing, and sustainable development. This underscores the critical need for investment across all levels of the U.S. bioeconomy. By making strategic investments in the bioeconomy now, the U.S. can position itself to capitalize on future innovations and advancements, unlocking the projected growth potential, which is expected to reach $400 billion by 2030. Investment in the U.S. bioeconomy not only promotes economic growth but also yields broader benefits, like fostering job creation, driving development of new technologies that enhance the quality of life, providing resilience to long-term prosperity, and staking out significant competitive advantage at the global scale. Overall, the U.S. bioeconomy represents a powerful force with immense potential, one that must be recognized and leveraged further.

Investment in the Bioeconomy Drives Regional Development

Given the vastness of the U.S. bioeconomy, a top-down approach alone will not be enough to drive the rapid growth needed for global competitiveness. A bottom-up approach, led by regional efforts, is essential for fostering growth and innovation across the country. Combining both approaches can boost the national GDP, stimulate regional economies, and create jobs. Regional programs like the EDA Tech Hubs, NSF Biofoundries, and U.S. Manufacturing Institutes like BioMADE and NIIMBL are already supporting localized bioeconomies, or micro-bioeconomies, tailored to specific resources and technologies.

While federal initiatives are important, it is equally important to assess their effectiveness. Understanding the return on investment from these programs is essential, not just for local micro-bioeconomies, but for their broader impact on the U.S. economy. For example, BioMADE has seen significant budget increases, including a $450 million boost in 2023, but its 2024 allocation of $75 million across 65 projects raises questions about fund distribution. As BioMADE supports more projects, further evaluation is needed to determine how effectively it is utilizing resources to advance U.S. biotechnology and biomanufacturing.

Ultimately, it will be essential for stakeholders in the U.S. bioeconomy to closely examine regional programs and assess their effectiveness. A comparative analysis of funding across different programs, agencies, and performance metrics will be necessary to ensure these investments are delivering tangible benefits and are aligned with broader bioeconomy goals. One key lesson from the Bioeconomy EO is that the U.S. must acknowledge that we can do more and that we have not yet done enough. The U.S. bioeconomy is still in its early stages, with significant room for growth and improvement. If the federal government and regional entities do not continue investing in this crucial sector, the nation will face serious economic, social, and global challenges in the future. Failing to act will only stifle progress and allow global competitors to surpass the U.S. in production, manufacturing, skill development, and resource acquisition. To ensure the U.S. bioeconomy thrives, sustained investment, decisive action, and a unified national and regional strategy are essential.

What Areas of the U.S. Bioeconomy Still Need Development?

The bioeconomy EO focused on many different components of the bioeconomy to grow and foster, but despite the EO’s best efforts, not all areas have developed to the same degree. Several areas still require further development, investment, and strategy to safeguard and grow portions of the U.S. bioeconomy.

One important area is Supply Chain Resiliency. In March 2024, the USDA published a report aimed at creating a more resilient biomass supply chain, in accordance with the deliverable in section 5C of the bioeconomy EO. Biomass is an important component of the U.S. bioeconomy but the bioeconomy supply chain encompasses much more. Resiliency should extend to ensuring that all material and intellectual inputs and outputs in the U.S. bioeconomy are safeguarded against disruptions, such as those experienced during the COVID-19 pandemic, and built to last. The pandemic exemplified our reliance on products made outside of the U.S. to keep our biomanufacturing ecosystem functioning, such as the need for single-use plastics or specific biological inputs for vaccine production. In light of this, achieving true resilience requires building a flexible, global supply chain to ensure access to diverse biological resources and the ability to rapidly adapt to global market demands, rather than relying solely on a U.S.-centric model. Establishing stockpile agreements and treaties will be key to ensuring the bioeconomy’s supply chain can withstand unforeseen challenges.

Another important aspect is Bio-Based Product Procurement. The bioeconomy EO included several deliverables focused on bio-based procurement, such as identifying procurement challenges, producing annual fiscal reports, and creating new procurement programs within different agencies. However, despite the emphasis on these issues, little has been published beyond a USDA report that offers generic recommendations to address challenges. These recommendations, such as measuring the bioeconomy and coordinating carbon intensity labels, fail to address the real difficulties that have hindered bio-based procurement at the federal level.

Additionally, Workforce Development & Bioliteracy is crucial for the success of the U.S. bioeconomy. To fully capitalize on the potential of the bioeconomy, a skilled workforce is required. While the OSTP has released an action plan to boost the bioeconomy workforce, further investment and coordination are necessary to meet the bioeconomy’s needs. The U.S. manufacturing sector has been the backbone of the economy since the industrial revolution, and transitioning to biomanufacturing offers the opportunity to create new jobs and bring substantial economic growth to regions across the country. However, this shift requires significant workforce development reforms, including reassessing immigration policies to ensure that the best global talent is attracted to the U.S., further strengthening the economy.

Strategic Next Steps for the U.S. Bioeconomy and the New Administration

To strategically foster the growth of the U.S. bioeconomy and remain globally competitive, the new administration must not only prioritize the development of currently underdeveloped areas within the bioeconomy but also establish the foundational infrastructure necessary for long-term success. A crucial first step would be establishing a clear and adaptable definition of the U.S. bioeconomy. This would help not only in measuring its progress but also in defining which sectors and sub-sectors fall under its umbrella.

Additionally, the administration should focus on regional development through the creation of micro-bioeconomies, which would diversify and strengthen the national bioeconomy. Implementing a bottom-up approach allows regions to tailor their strategies to local strengths, like existing industries, academic institutions, or workforce capacities, while aligning with broader federal priorities. This could involve reskilling and redeploying existing manufacturing capacity into biomanufacturing, leveraging local resources, talent, and infrastructure. These efforts would not only support economic growth and job creation at the regional level, but also enhance national resilience by decentralizing production and fostering innovation across the nation.

To support this regional strategy, the federal government must provide a comprehensive national framework based on clear goals and achievable metrics. For instance, a target such as increasing the production of bio-based products by 50% by 2050 for domestic consumption could help coordinate efforts across various agencies and set a clear path for growth. Furthermore, the federal government should focus on providing the necessary infrastructure for biotechnology and biomanufacturing development, not only physical infrastructure, such as processing facilities and biomanufacturing plants, but also intangible infrastructure like workforce development, talent enhancement, financial mechanisms, and intellectual property creation. The Trump administration could also lead in advancing bio-based material production and green chemical production through novel biotechnologies. These efforts would not only benefit American consumers by providing sustainable alternatives to essential products but would also strengthen national security and defense positions.

The Trump administration presents significant opportunities to advance the bioeconomy, but it must also carefully navigate the wide-ranging activities the sector encompasses. Policy changes, particularly cuts to funding for scientific research and development, could have unintended consequences that hinder progress. While some repealed executive orders may not have directly affected the sector, reductions in funding for science and education are likely to create ripple effects, such as a shortage of trained workers or disruptions in the supply chain, which could trigger cascading negative impacts. Therefore, thoughtful and strategic decision-making is crucial to ensuring the bioeconomy reaches its full potential.

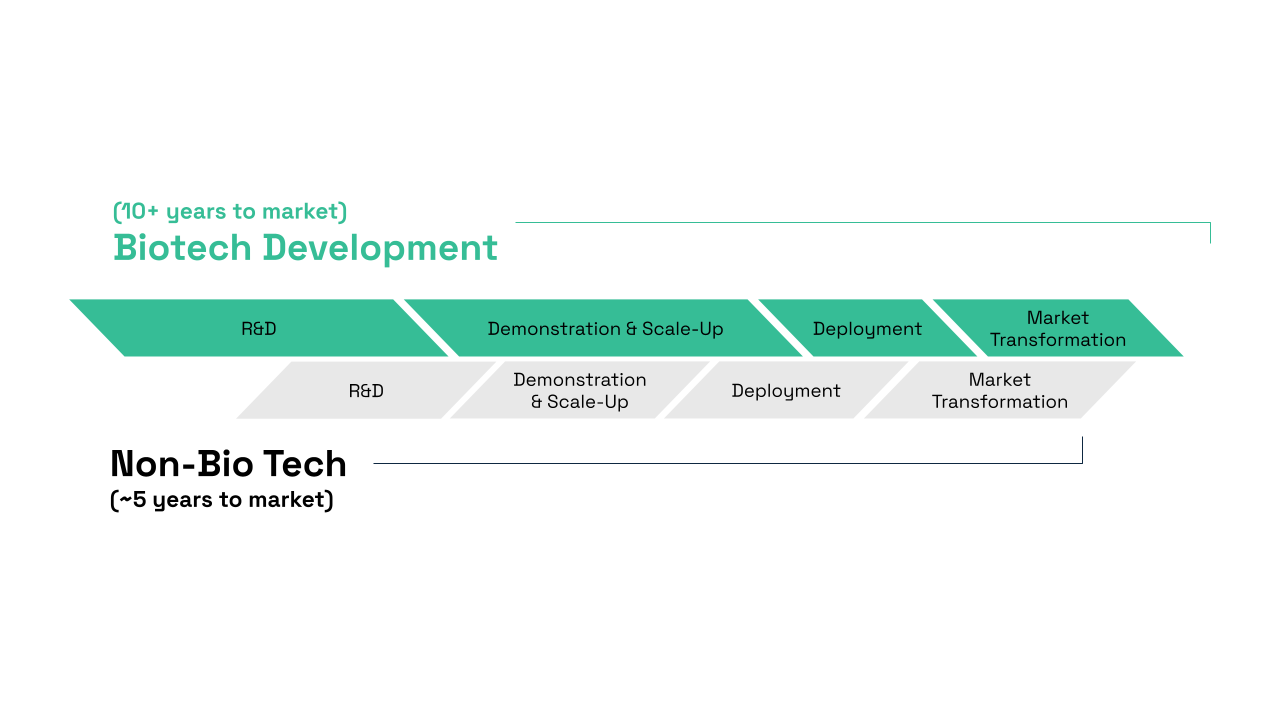

While the U.S. has made significant advancements and remained a global leader in biotechnology over the past decade, the next four years will be critical in determining whether it can sustain that leadership. According to the National Security Commission on Emerging Biotechnology, China has prioritized biotechnology and, by extension, the bioeconomy for the past 20 years and is rapidly advancing toward dominance in the field unless the U.S. takes decisive action. Meanwhile, the Netherlands recently announced an investment of approximately €1.3 billion to expand its biotechnology sector, with the goal of becoming a global leader by 2040. This growing international investment signals rising global competition, and the U.S. must strengthen its bioeconomy to stay ahead. The Trump administration does not need to start from scratch; it can build on the accomplishments of its first term and the progress made since.

The Emerging Reach of the Bioeconomy

On Tuesday, 4/8/25, the bipartisan National Security Commission on Emerging Biotechnology (NSCEB) released their findings on how the U.S. can support and bolster the emerging bioeconomy sector. This sector, which includes biotechnology and biomanufacturing, is increasingly important to scientists working across disciplines – and will continue to shape the economic fortunes of regions across the country.

FAS looks forward to dissecting, advancing, and advocating for the Commission’s report. FAS has been active and influential in this sector and has worked with various stakeholders and experts to advance evidence-based policy recommendations to boost the U.S. bioeconomy (more below). While the report provides an essential starting point to grow and secure our biotechnology and biomanufacturing enterprise, it will be important to advocate for the recommendations found within it, but also to add and refine recommendations to meet the ever evolving U.S. bioeconomy.

FAS is especially enthusiastic about the recommendations that emphasize prioritizing and advancing biotechnology at the national level, ensuring the U.S. maintains its innovation edge. We also strongly support the recommendations aimed at scaling biotechnologies and biomanufacturing by fostering private sector growth and leveraging various financial mechanisms. These recommendations are crucial in addressing some of the most urgent challenges facing the U.S. bioeconomy and will serve as a vital step toward establishing a dynamic and adaptable national strategy for the sector. See our policy statement for more details.

Cautious and Enthusiastic Interest

While FAS is optimistic of the impact that this report can have, it is also important for FAS to be cautious around national security issues due to our 80 year old legacy. FAS began in response to how new technologies (nuclear) could be used for war (nuclear weapons). Today we remain watchful of technologies with the potential of misuse. FAS team members involved with national security take an understandably cautionary approach. The confluence of technology and access mean that there is risk associated with bio-products, too. “This opportunity must also be balanced with a clear-eyed understanding that increasing economic competition, heating geopolitics, and advancing life sciences capabilities may change how countries and other actors view the utility of globally repugnant capabilities such as biological weapons.” said Yong-Bee Lim, Associate Director of Global Risk at the Federation of American Scientists.

The report details the importance of safeguarding the biotechnology and biomanufacturing enterprise to remain competitive at the global scale, especially with China (recall the recent semiconductor shortages). However, “it’ll be important to balance both innovation capabilities and risk as we work towards ensuring that the U.S. bioeconomy is a priority area for both the Nation and for National Security.” said Nazish Jeffery, Bioeconomy Policy Manager at the Federation of American Scientists.

Bioeconomy Presents Significant Opportunities

Still, FAS continues advocating and promoting this area with great enthusiasm. The nascent bioeconomy is more than just leading edge biology meets computational gains. There are a myriad of scientific, economic, and social benefits to be had by leveraging this new industry.

No one at FAS knows this better than Nazish Jeffery, who spearheaded efforts to understand this moment. For more than two years she has worked with biologists, technologists, policymakers and biotechnology companies to investigate how the U.S. can maintain competitiveness while distributing economic rewards equitably domestically.

FAS sponsored policy sprints, which are open calls for participants in academia and industry to submit and develop actionable policy memos that address a particular issue or sector. The goal is to infuse diverse perspectives and expertise into policy that improves lives for all Americans. Since the start of the Commission’s investigations, FAS has sponsored policy sprints on topics such as the intersection of biology and artificial intelligence, as well as a sprint soliciting ideas to grow the bioeconomy sector itself.

This emerging technology sector brought in $210 billion into the U.S. economy in 2023, and is projected to grow to $400 billion by 2030. The economic potential of the bioeconomy is significant; policymakers should promote and work in partnership with industry to continue development in distributed regions across the U.S. to invigorate innovation and enable job creation. This opportunity must also be balanced with a clear-eyed understanding that increasing economic competition, heating geopolitics, and advancing life sciences capabilities may change how countries and other actors view the utility of globally repugnant capabilities such as biological weapons.

FAS interviewed, worked with, or sought input from numerous academics, technologists, bio-industry leaders, elected representatives, and organizations, to understand the full spectrum of the value chain and push forward the best ideas.

FAS invites you to take a look at what possibilities lay ahead, presented below.

Bioeconomy Policy Sprint

The FAS Bioeconomy Sprint produced actionable policy memos to strengthen the bioeconomy in concert with outside expertise, including:

- A Matter of Trust: Helping the Bioeconomy Reach Its Full Potential with Translational Governance by Christopher Gilliespie

- BioNETWORK: The Internet of Distributed Biomanufacturing by Justin C. Sanchez

- Coordinating the U.S. Government Approach to the Bioeconomy by Sarah R. Carter

- Strengthening the U.S. Biomanufacturing Sector Through Standardization by Chris Stowers

- Accelerating Biomanufacturing and Producing Cost-Effective Amino Acids through a Grand Challenge by Allison Berke

- Project BOoST: A Biomanufacturing Test Facility Network for Bioprocess Optimization, Scaling, and Training by Ed Chung & Charles Fracchia

- Advancing the U.S. Bioindustrial Production Sector by Michael Fisher

- Accelerating Bioindustry Through Research, Innovation, and Translation by Jon Roberts

Bioeconomy x AI Policy Sprint

Artificial intelligence continues to develop exponentially; these recommendations can scale alongside AI and deliver substantial benefits:

- Develop a Screening Framework Guidance for AI-Enabled Automated Labs by Tessa Alexanian

- An Evidence-Based Approach to Identifying and Mitigating Biological Risks From AI-Enabled Biological Tools by Richard Moulange & Sophie Rose

- A Path to Self-governance of AI-Enabled Biology by Oliver Crook

- A Global Compute Cloud to Advance Safe Science and Innovation by Samuel Curtis

- Establish Collaboration Between Developers of Gene Synthesis Screening Tools and AI Tools Trained on Biological Data by Shrestha Rath

- Responsible and Secure AI in Production Agriculture by Jennifer Clarke

Additional Bioeconomy Research

Given the ongoing cost curve declines of compute, increased access to data, and growing interest in this emerging sector, FAS continues to investigate a range of related topics. Some recent work includes:

- Understanding the U.S. Bioeconomy: Agency Perspectives

- The U.S. Bioeconomy Needs Biomass, But What Is It and How Do We Use It?

- The Importance of Standards for the U.S. Bioeconomy & National Security: A Conversation with Congressman Jake Auchincloss

- Bold Goals Require Bold Funding Levels. The FY25 Requests for the U.S. Bioeconomy Fall Short

- Regulations, funding, and knowledge gaps: Challenges and opportunities in bringing agricultural biotechnology to market

- The U.S. Bioeconomy is Not Yet Sustainable. Here’s What Needs to Change.

- Implementing the Bioeconomy Executive Order: Lessons Learned and Future Considerations

- Wins, Gaps, & Looking Forward in the U.S. Bioeconomy

- “The US needs to lean into an old strength”: Maintaining Progress and Growing US Biomanufacturing

FAS will continue to work in this important area. Ongoing work related to the U.S. bioeconomy will be regularly updated here: https://fas.org/initiative/bioeconomy/

Position on National Security Commission on Emerging Biotechnology Final Report: Charting the Future of Biotechnology

The Federation of American Scientists supports the National Security Commission on Emerging Biotechnology’s Final Report and the Recommendations contained within it.

Charting the Future of Biotechnology delivers 49 recommendations to foster the growth of the biotechnology and biomanufacturing sector within the U.S. bioeconomy. Implementing the recommendations outlined in this report will strengthen the U.S. bioeconomy by establishing a unified national strategy that fosters innovation in biotechnology, ensures our continued global competitiveness, and delivers significant economic and societal benefits to the nation.

FAS is particularly excited by these recommendations:

- 1.1a: Establishment of a National Biotechnology Coordination Office

- 2.2a-d: Economic levers to promote scale-up and innovations coming to market

- 2.4a: Biotechnology infrastructure and data to be classified as “critical infrastructure”

- 3.1a: Department of Defense to consult with stakeholders to define principles for ethical use of biotechnology

- 4.3a-c: Centers for Biotechnology

- 5.1a through 5.3b: Biotechnology workforce for the future

- 6.1a-e: Strengthen global U.S. biotechnology efforts through global policy

These recommendations have the potential to address key challenges within the U.S. bioeconomy, including the lack of a coordinated strategy, commercialization barriers, workforce shortages, and supply chain vulnerabilities.

“FAS applauds the NSCEB’s deep investigation of unlocking U.S.-led biotechnology in the Fourth Industrial Revolution. We look forward to bringing FAS’s unique and effective approach of policy entrepreneurship to realize the promise of these capabilities while reducing the risks of misuse,” said Yong-Bee Lim, Associate Director of Global Risk at the Federation of American Scientists.

“The National Commission on Emerging Biotechnology report developed 50 recommendations to address the major challenges currently facing the U.S. bioeconomy: a lack of strategy and coordination across the federal government, difficulties in scaling biotechnology innovations, and the need for a trained workforce for the future. These recommendations aim to de-risk the biotechnology sector, thereby enabling private sector investment in critical biotechnology and biomanufacturing initiatives. Ultimately, these efforts will foster continued growth, secure the U.S. bioeconomy, and lead to the creation of new jobs and further economic growth.”” said Nazish Jeffery, Bioeconomy Policy Manager at the Federation of American Scientists. “It will be important to continue advocating, refining, and adding additional recommendations in order to realize the full value that this report offers.”

For more information contact Nazish Jeffery, FAS Bioeconomy Policy Manager, njeffery@fas.org.

Understanding the U.S. Bioeconomy: Agency Perspectives

The U.S. bioeconomy—defined by the National Institute of Standards and Technology (NIST) as “economic activity derived from the life sciences, particularly in the areas of biotechnology and biomanufacturing, including industries, products, services, and the workforce” and valued by some at ~$1 trillion—has been a major focus of policy development over the past few years. These policy advances include the White House Executive Order on “Advancing Biotechnology and Biomanufacturing Innovation for a Sustainable, Safe, and Secure American Bioeconomy” (Bioeconomy EO), the CHIPS & Science Act, and the Inflation Reduction Act (IRA). In March 2024, the Office of Science and Technology Policy (OSTP), announced the launch of the National Bioeconomy Board (NBB). The board will “partner across the public and private sectors to advance societal well-being, national security, sustainability, economic productivity, and competitiveness through biotechnology and biomanufacturing,” highlighting the Biden Administration’s commitment to future-proofing an economically sustainable U.S. bioeconomy.

Despite these advances, the vast intersectionality inherent to the bioeconomy (e.g., with health, clean energy, national security, climate change, economic development) poses unique challenges for the U.S. government. This complexity makes it difficult for the various agencies to coordinate and even more difficult for the general public to understand the government’s approach to the bioeconomy. Nonetheless, to maintain the continued growth within the bioeconomy that has resulted from these policy advances, it will be imperative to clarify a strategic vision that coordinates and publicizes governmental efforts that support the burgeoning U.S. bioeconomy.

The NBB can play an important role in promoting this strategic vision. As directed by the Bioeconomy EO, the interagency through the Executive Office of the President set up the NBB to promote interagency coordination and collaboration on the bioeconomy. The NBB is co-chaired by OSTP, the Department of Commerce (DOC), and the Department of Defense (DOD), and nine other agencies make up the entirety of the board. Other agencies not represented on the NBB itself, including the Environmental Protection Agency (EPA), work with the NBB through various working groups and play an integral role.

To understand the range of governmental priorities for the bioeconomy, the overarching strategy, the work underway, the various programs within the agencies, and the role of environmental sustainability, our team at the Federation of American Scientists (FAS) spoke with key agencies represented on the NBB to collect their perspectives.